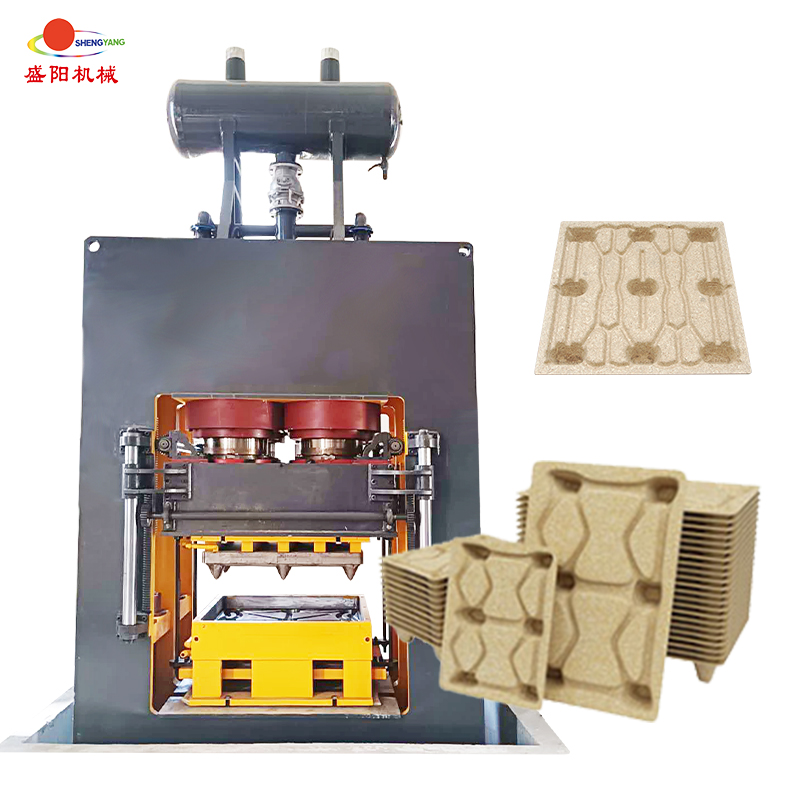

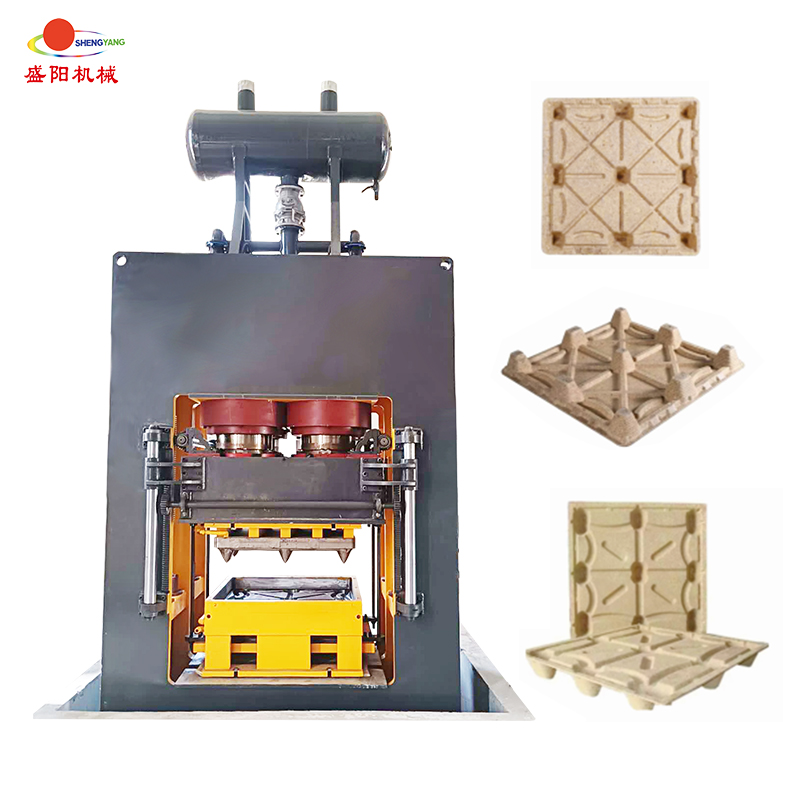

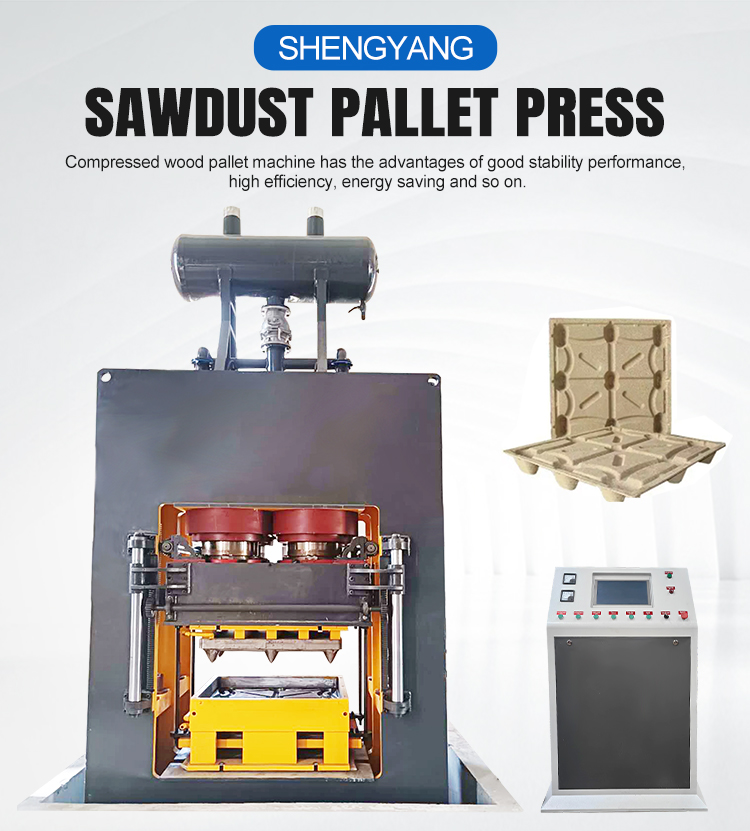

Automatic Sawdust Pallet Press Sawdust Pallet Making Machine

Features:

2) High density: 800-850 kg/m3.

3) Waterproof, anticorrosive, insect-resistant, low flammability, suitable for outdoor use.

4) Environmentally friendly (E1), 100% biodegradable.

5) Fumigation-free: Our molded pallets are made of wood fibers through high pressure and high temperature during the production process.

They are bonded by resin and are mold and insect resistant. No fumigation or heat treatment is required for export to ISPM15 compliant countries.

6) Reasonable design makes our products have the advantages of saving storage space, light weight and exquisite appearance.7) Large loading capacity, strong and durable physical characteristics and long service life.

8) One time molding, without any metal parts.

1) Crush wood into small pieces or use wood chips and sawdust;

2) Drying the material to about 8-10% moisture;

3) Mixing the raw material with glue;

4) Making pallets from it.

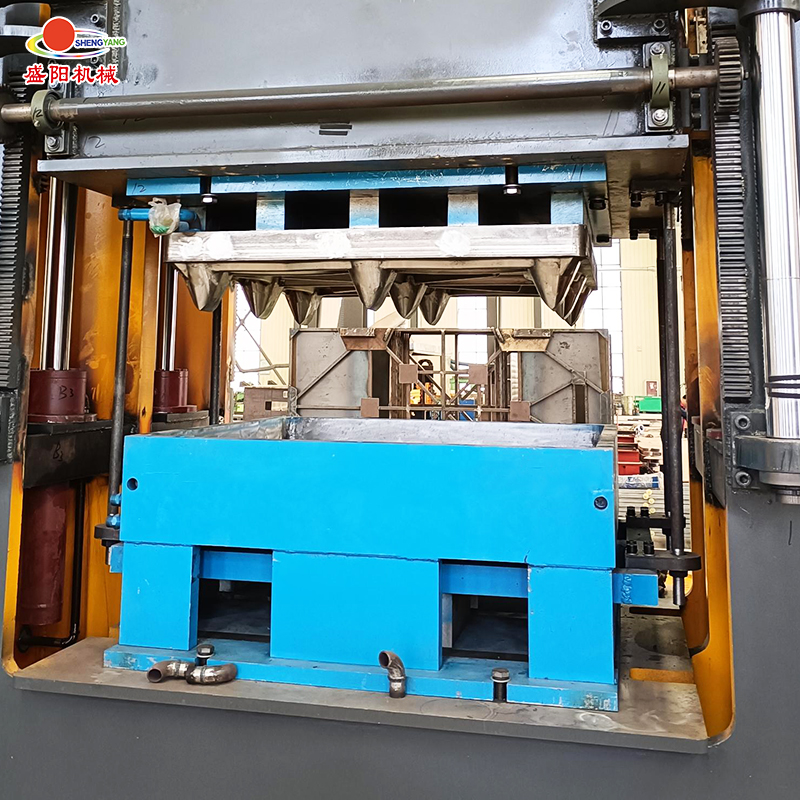

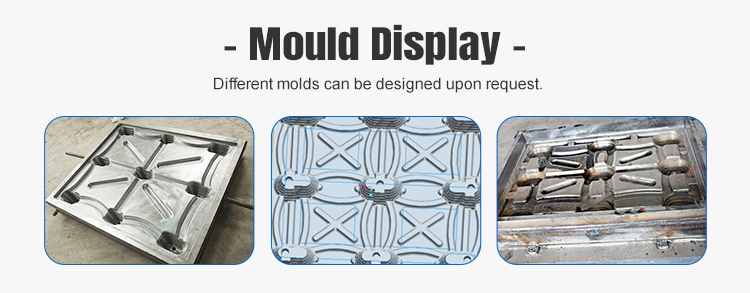

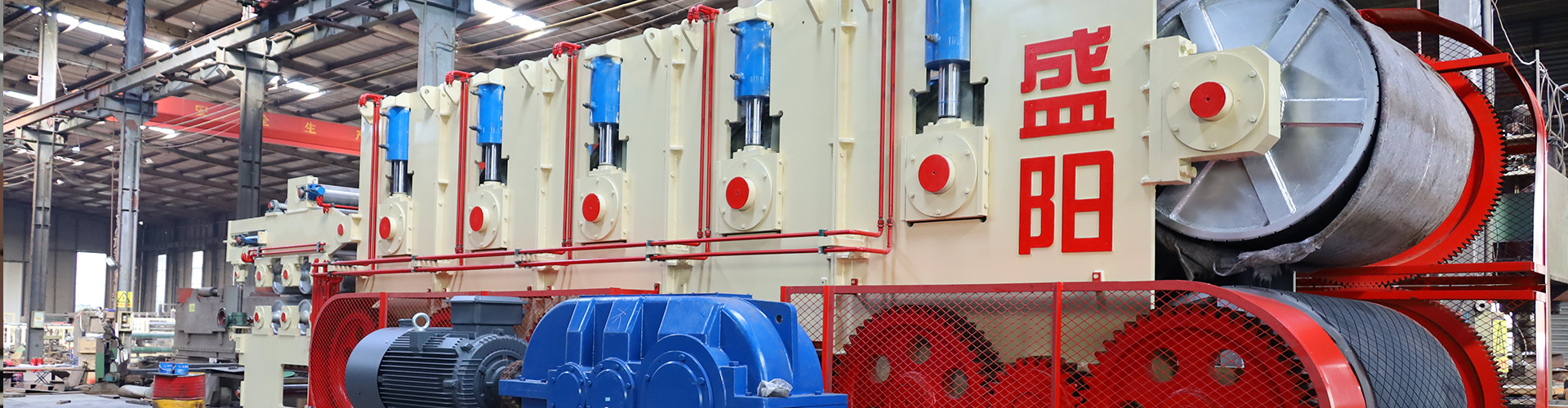

The main equipment of this production line consists of a series of chippers, crushers, dryers, glue mixers, hot presses, etc.

The raw materials are chipped and crushed into wood chips of a certain length, and then enter the dryer to dry the excess moisture.

Add glue to the dried wood chips and stir them thoroughly. The mixed material can be filled into the mold and hot-pressed.

After hot-pressing, the molded molded tray can be taken out.

We can provide automated production solutions, including automated dosing and feeding, automated mixing, unloading,

feeding and other automated technologies that save labor and operations, and can effectively run 24 hours a day.

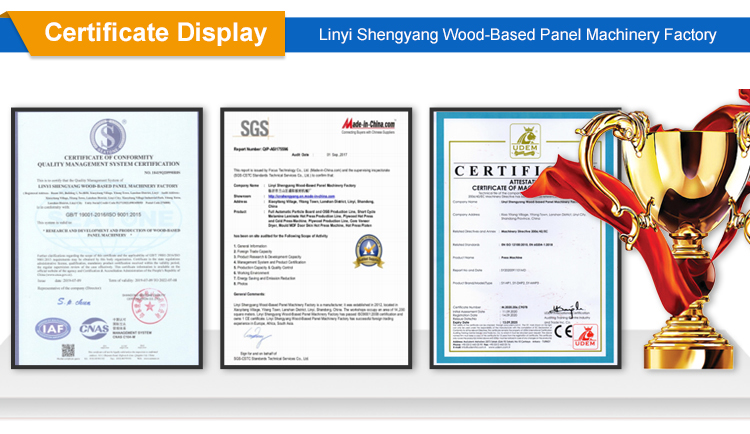

LinYi ShengYang Wood Based Panel Machinery Factory established in 1996 is a professional manufacturer

engaged in the research,development, production, sale and service of particle board production line, MDF production line,

OSB production line, plywood production line, and all kinds of hot press and cold press machine. We are located in Lin Yi

City with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced

staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our

company has introduced a series of advanced equipment and leading technology. In addition, we have obtained certificates ISO 9001 and CE.

Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as India, Vietnam,

Malaysia, Indonesia, Africa, South of America, Russia, etc. We also welcome OEM orders. Whether selecting a current product from our catalog

or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

We will carry on, serve you with the more excellent products quality, more stringent management system, and much better service system.

And, hand in hand, and share success with you, trust us, once cooperative, long-term friends.

All We ShengYang Men welcome your visit.

1. Can you customize products for clients?

Yes, We can customize and produce woodworking machines according to the customer’s requirements or drawings.

2. How can we trust your factory?

We recommend that you come to our factory to see the goods, to verify the real situation of the products, and know more about our factory.

3.Why does the price often change?

The price depends on the latest prices of the raw materials.

4. What about the contract signing?

If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit.

Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax.

We will ensure the quality of the products and the accessories are complete.

5. How about delivery?

when the product is ready, it can be delivered to you after your full payment.

We’ll provide technical guidance.

You Might Also Like

+86 15963926799

+86 15963926799 Yitang Town,Linyi,Shandong,China

Yitang Town,Linyi,Shandong,China