Automatic Veneer Peeling Line

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

|

Warranty of core components |

1 Year |

|

Core Components |

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear |

|

Place of Origin |

Shandong, China |

|

Warranty |

1 Year |

|

Key Selling Points |

Easy to Operate |

|

Applicable Industries |

Manufacturing Plant, log debarker machine |

|

Showroom Location |

None |

|

Weight (kG) |

3200 |

|

Condition |

New |

|

Peeling Rate |

100% |

|

Wood Loss Rate |

less 1% |

|

Wood Length Range |

1350--2650mm |

| Voltage |

380/415 can be customized |

|

Power |

29.5 KW |

|

Dimension(L*W*H) |

2800x2000x1250 mm |

|

Product name |

Log debarker machine |

|

Function |

peeling wood surface |

|

Diameter of peeling log |

30 -500 Mm |

|

cylinder diameter |

80mm |

|

Line speed |

45 m/min |

|

Clipping knife |

1500*18*16mm |

|

Max working Size |

500*1400mm |

|

Production dimension |

4000*2200*1800mm |

|

Keywords |

Wood Log Tree Debarker Machine |

|

Advantage |

High Effiency |

Plywood Production Technology:

1) Log cutting:

Usually import log length is more than 6 meters. Cutting according to the technology required length and quality. The cutting length should be product length add remains. For example, product is 1220mm*2440mm, cutting length usually be 2600mm or 1300mm.log length, camber and demerit affect plywood output directly. Remains are small wood pieces, truncations, sawdust, tec. Log cutting wastage ratio is 3%-10%.

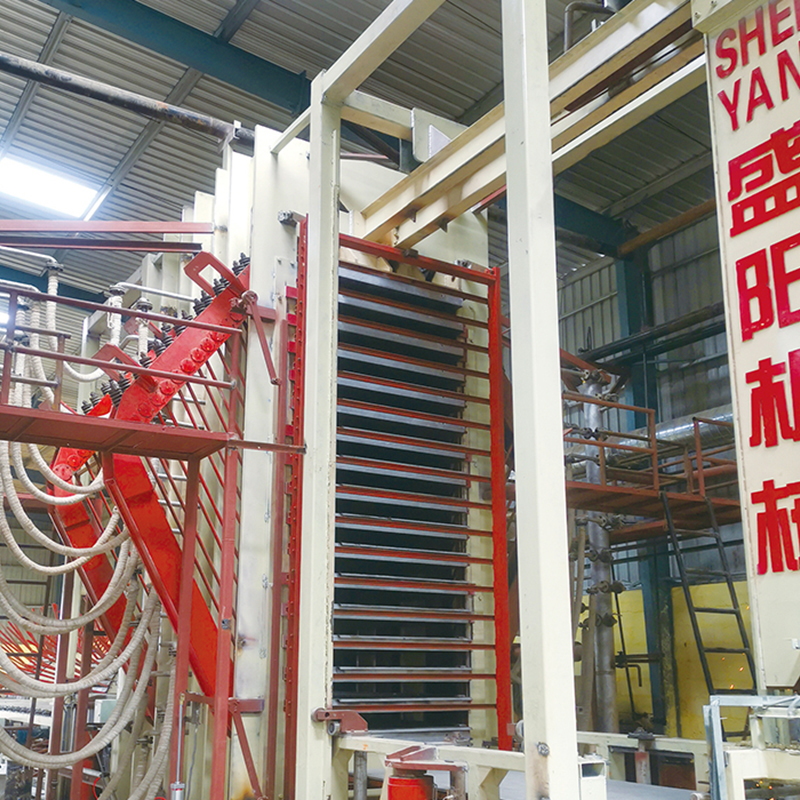

2)Veneer peeling:

Peeling is the most popular plywood producing process. Back veneer thickness is about 0.6mm, core veneer and centre veneer thickness is about 1.8mm.

3) Drying:

Veneer is moist. it should be dried according to the technology requirement. After drying, it will shrink. Dimension will become smaller. Veneer length, width, thicknesswill shrink. Shrink wastage is related to wood material, moisture containing, veneer thickness. Shrink wastage is 4%-10%.

4) Veneer gluing and handling:

Handling include cutting, putting veneer together and mending. Cut zonal veneer into specification veneer or proper size which can be put together. Narrow zonal veneer can be put together into one veneer. Veneer with demerit can be mended to be qualified.Wastage in this part related to log material, peeled veneer quality, dried quality, and worker operation skill. Wastage ratio is 4%-16%. Import veneer processing plywood wastage ratio is 2%-11%.

5) Cold and Hot press:

Veneer be glued and stacked, then glue together under set temperature and pressure by hot press. As veneer temperature and moisture containing changes, veneer will shrink. Shrink wastage is related to temperature, pressure, hot press time, wood material, moisture containing,wastage ratio is 3%-8%

6) Edge trimming:

Trimming the edge of the plywood flank from hot press to qualified plywood board. Remains related to process remains and product dimension. Production is bigger, wastage is smaller.Wastage ratio is 6%-9%.

7) Sanding:

Sanding plywood surface to make it good. Wastage is powder. Veneer quality is good, sanding is less. Wastage ratio is 2%-6%.

Other machines

We can also provide other machines, just like veneer jointer machine, knife grinder and so on.

It can be customized according to client's requirement.

We have more than 20 years of production custom experience, welcome interested friends to visit our factory.

Shandong Menglianggu Machinery Manufacturing Co., Ltd. was new established in 1996. We have been deeply involved in the wood based panel machinery industry for 20 years, and have many industry equipment design experts. We focus on the R&D and manufacturing of a full set of wood based panel machinery and equipment, and provide the whole plant planning and design scheme. The main products include a full set of high grade plywood production equipment, automatic particleboard production line and oriented particleboard production line and other industrial equipment.

We will provide you with professional customized service, quality and after sales guarantee. Your satisfaction is the goal we pursue. Thanks for the trust and support from friends all over the world.

We will live up to expectations and strive to move forward. I believe we will become your closest partner.

You Might Also Like