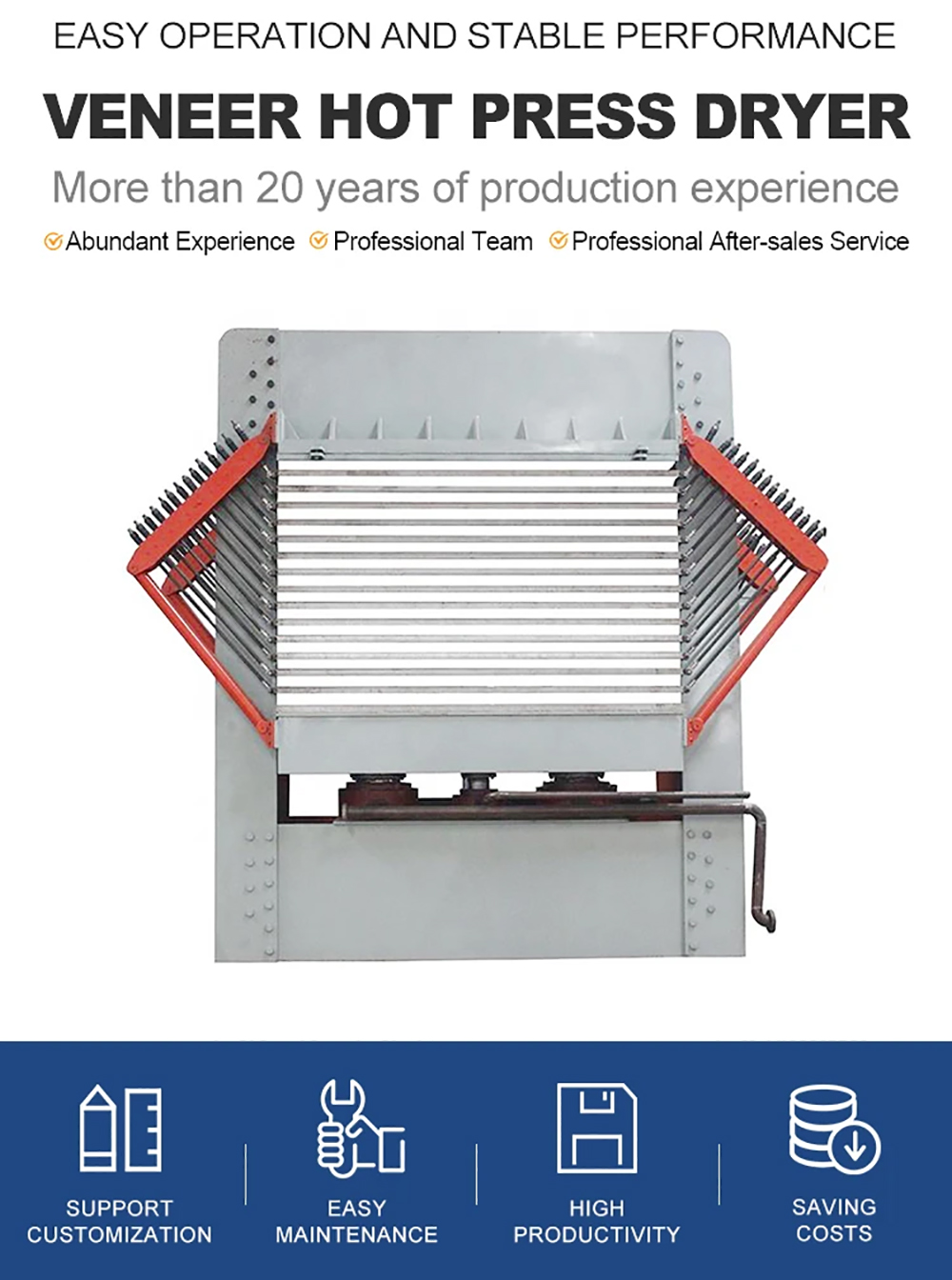

Square Tube Veneer Dryer

Place of Origin | Shandong,China |

Condition | New |

Type | VENEER DRYER |

Weight (kG) | 4500 kg |

Applicable Industries | Manufacturing Plant, Plywood Plant |

Warranty | 1 Year |

Key Selling Points | High Productivity |

Usage | veneer drying |

| Voltage | 80V or as your requirements |

Dimension(L*W*H) | 3200mm*1300mm*2000mm |

Power (kw) | 3 |

Video outgoing-inspection | Provided |

Core Components | Bearing, Motor, Pump, Gear, PLC, Gearbox, Pressure vessel, Engine |

Normal pressure | 50T/Customizable |

Layers | 15-20/Customizable |

PLC | Simens PLC |

Hydraulic controlling methods | Automatic control |

After-sales Service Provided | Engineers/Engineers Online |

Square tube thickness | 4*6*3mm |

Feeding direction | Transverse |

Motor power | 15kw+2KW |

Distance between layers | 60mm |

Normal oil pressure | 15 Mpa |

Hot platen size | 2700*1370*42 mm or according to your need |

Weight of whole machine | 28,000 kg |

Plywood core veneer drying machine is an important part in plywood processing.After peeling, you get fresh veneer.

For long stock or next plywood making process, we need remove water and moisture, so you need core veneer dryer or drying line.

All parameters are customized.

There are mainly four type, breath type drying machine, square tube veneer dryer, roller type drying line and Mesh belt type

drying line.

Remarks:

We can produce it according to your request. Welcome drawings from you.

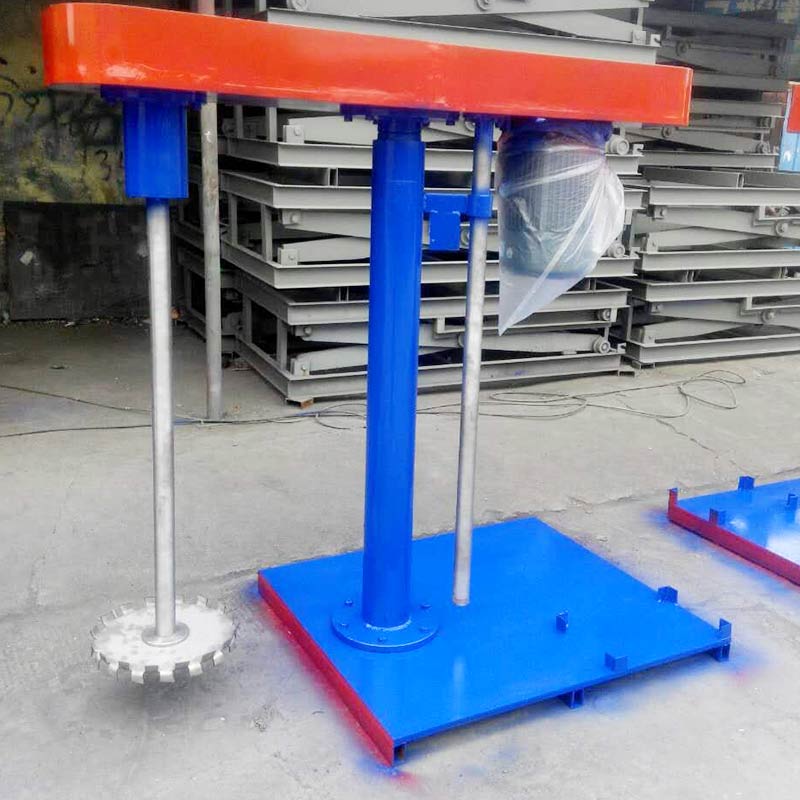

Synchronous Closer

A simultaneous shutdown device allows the dryer to shut down at the same time, ensuring that all veneers are dried for the same amount of time to achieve the same moisture.

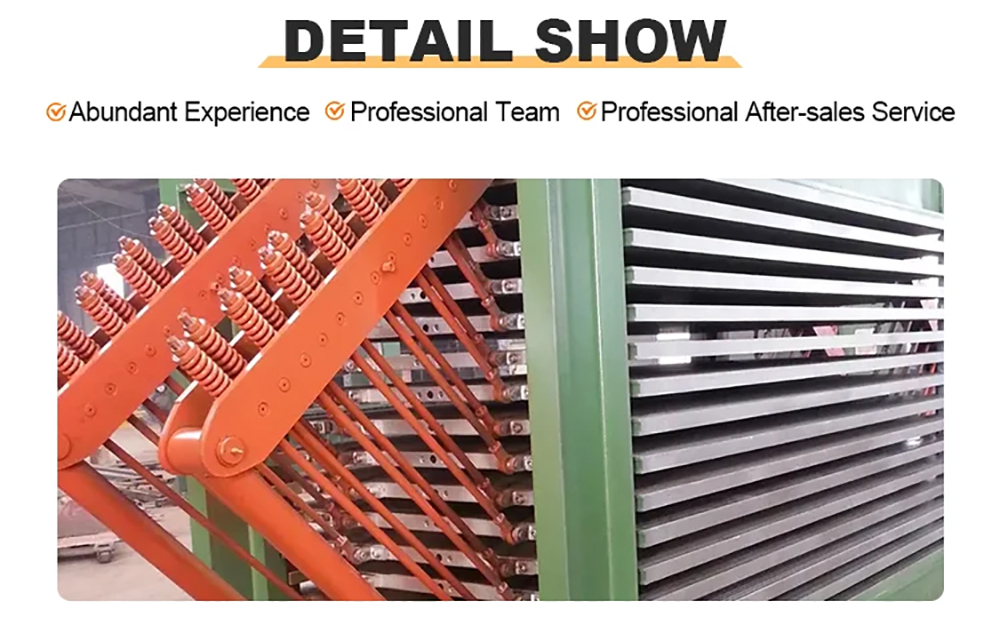

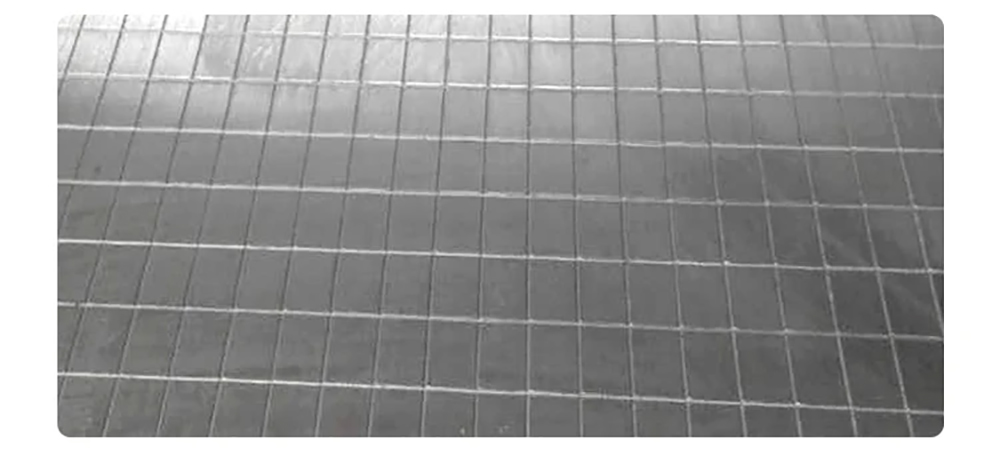

Grooved Hot Platen

Special for core veneer dryer use, easy to breath out moisture when drying.

High quality raw materials

Frame made from high quality steel with advanced welding technique.

Pre-sale services:

1. Provide the free consultation of the equipment

2. Provide the standard device and the flow chart

3.According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

4.Dedicated personnel are available to entertain and visit the factory

Services during the sales:

1.Strictly inspect the machine before shipment

2.Expatriate personnel teach installation

3.Train the first-line operator.

After-sale services:

1.24 hours online service

2. Provide the VIDEO with Install and debug the equipment

3.Provide remote guidance from professionals

FAQ:

1. Can you customize products for clients?

Yes, We can customize and produce woodworking machines according to the customer’s requirements or drawings.

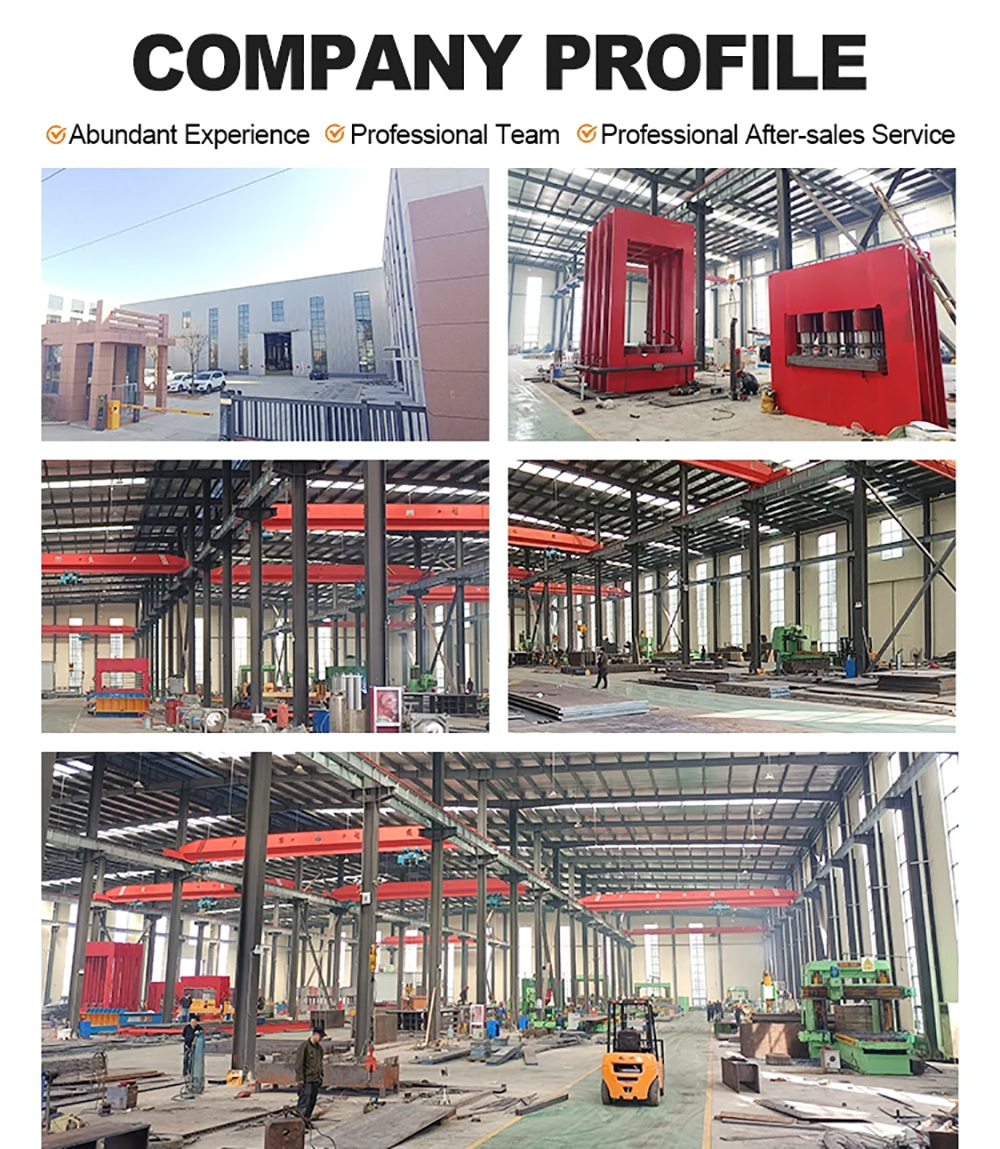

2. How can we trust your factory?

We recommend that you come to our factory to see the goods, to verify the real situation of the products, and know more about our factory.

3.Why does the price often change?

The price depends on the latest prices of the raw materials.

4. What about the contract signing?

If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit. Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

5. How about delivery?

When the product is ready, it can be delivered to you after your full payment. We’ll provide technical guidance.

You Might Also Like