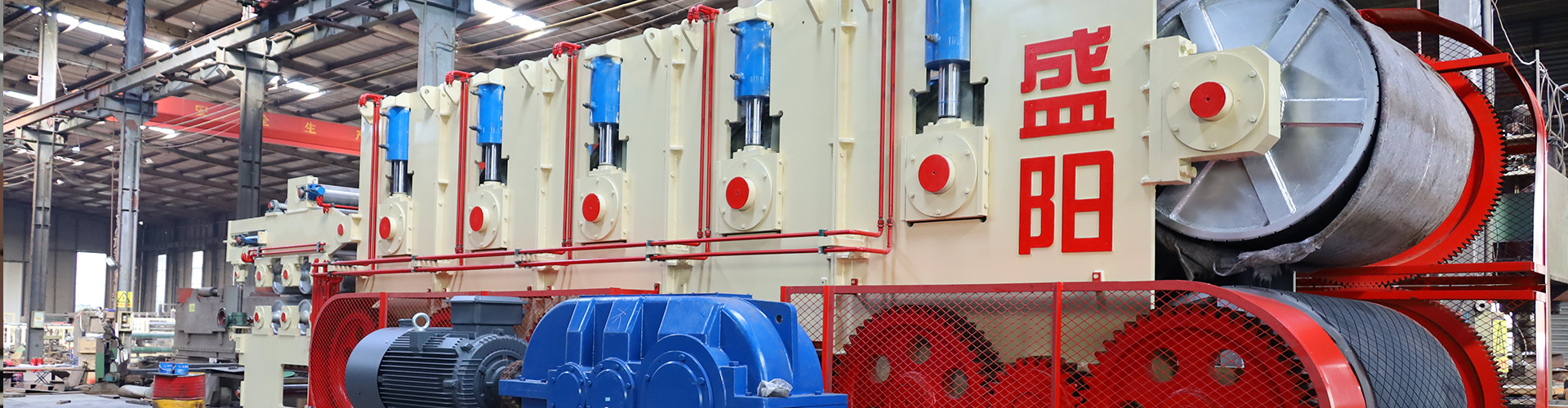

Spindleless Veneer Peeling Machine

|

Place of Origin |

Shandong, China |

|

Condition |

New |

|

Type |

Log Debarker |

|

Weight (kG) |

6500 kg |

|

Applicable industries |

Building Material Shops, Manufacturing Plant,Other, wood, woodworking machinery factory veneer peeling factory, wood-based machinery panel factory |

|

Warranty |

1 Year |

|

Key Selling Points |

High Safety Level |

|

Usage |

Wood Debarkers |

| Voltage |

380V |

|

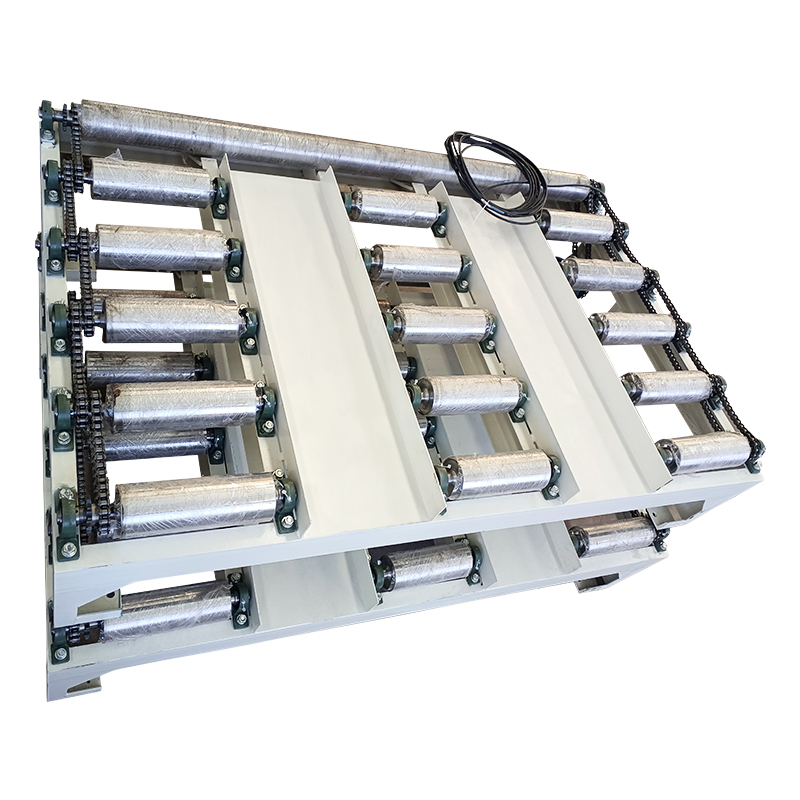

Dimension(L*W*H) |

4700*2300*1500mm |

|

Power (kw) |

11 |

|

Video outgoing-inspection |

Provided |

|

Warranty of core components |

1 Year |

|

Core Components |

Bearing, Motor, Pump, Gear, PLC, Other, Gearbox Pressure vessel, Engine, Other |

|

After-sales Service Provided |

Technical Online Service |

|

Color |

customize |

|

Product name |

Veneer Peeling Machine |

|

Keywords |

Wood Log Tree Debarker Machine |

|

Working methods |

Fully Automatic |

|

Steel material |

Superior Standard |

| Veneer thickness |

0.8-3.5mm |

|

Panel Length(mm) |

60mm |

|

Max log diameter |

600mm |

|

Min log diameter |

30mm |

|

Max log length |

1300mm |

|

Veneer thickness |

0.8-4mm |

|

Speed |

57m/min (Speed can be adjusted) |

|

Feeding |

7.5KW |

|

Cutting |

4KW |

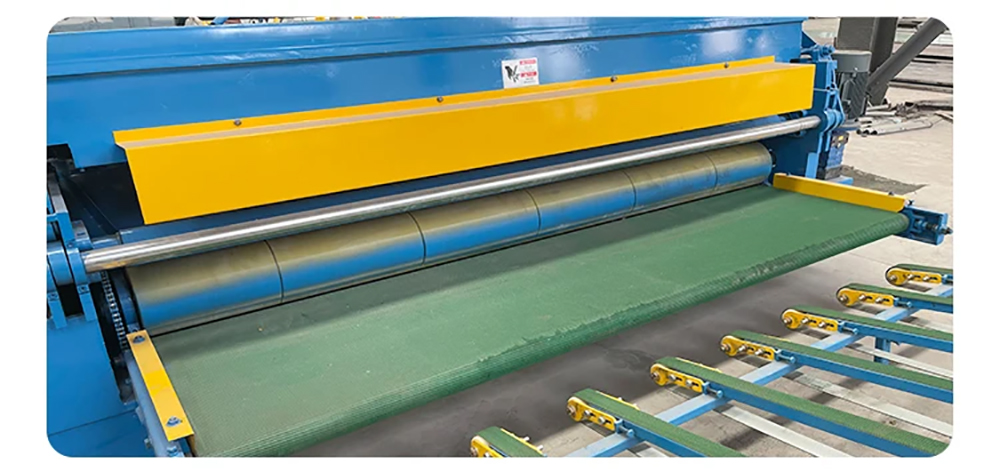

Specially fitting for hard wood, more stable and more durable ,as well as the produced veneers are with higher accuracy.

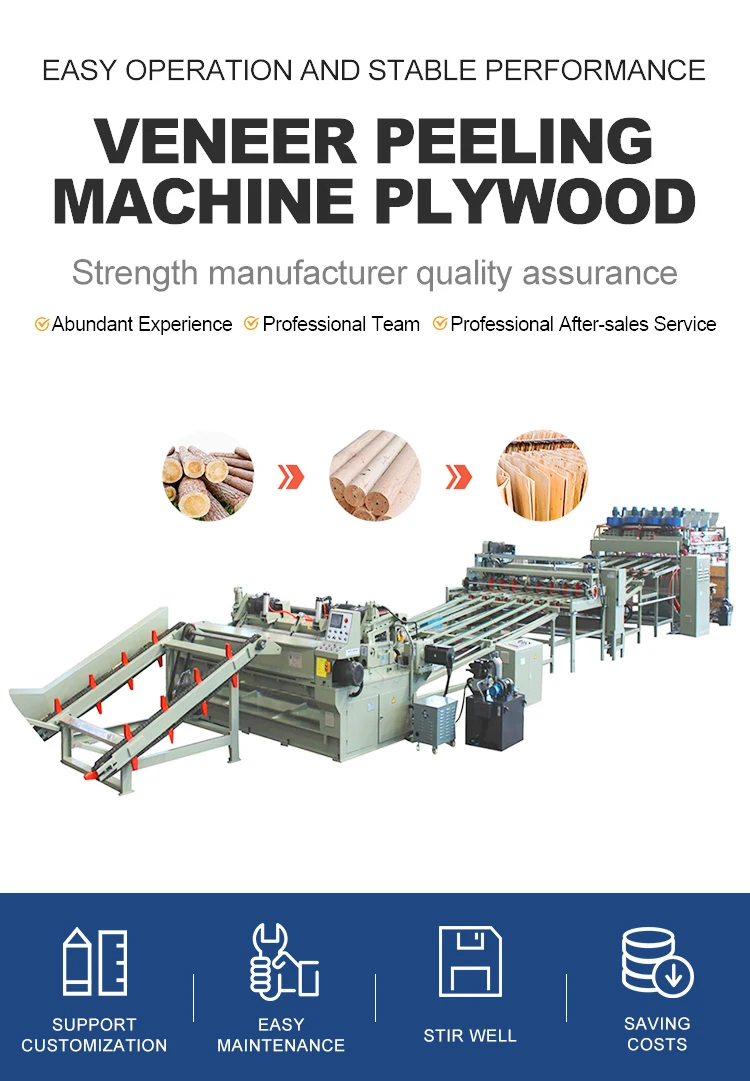

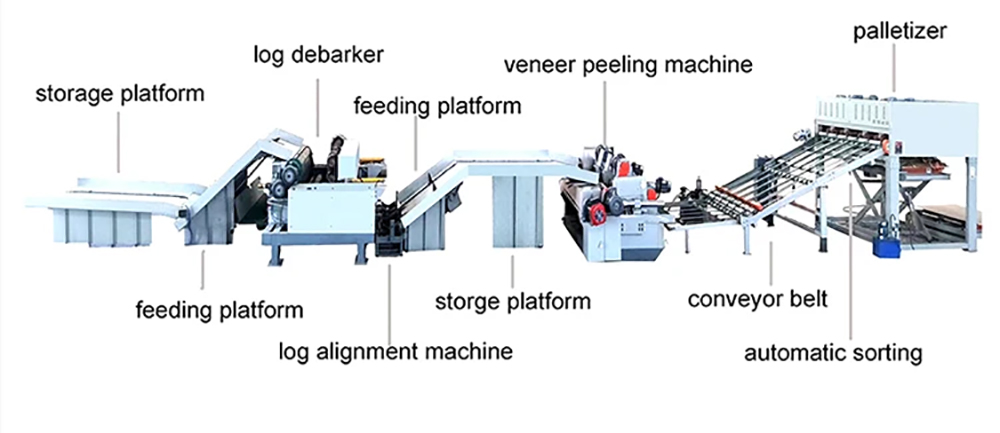

The veneer peeling line not only improves the quality and precision of veneer production, but also greatly improves the production efficiency and the degree of automation of the whole machine.

The veneer peeling line is one of the main equipment for producing plywood. We can provide veneer peeling machine, Automatic Stacker machine and Wood Log Debarker and the related knife grinding machine.

Remarks:

We can produce it according to your request. Welcome drawings from you.

Advanced Technology

High Efficiency

Servo Feeding Motor

Veneer Peeling Production Line

A complete automated veneer peeling line includes log peelers, infeed conveyors, veneer peelers and stackers.

You Might Also Like

+86 15963926799

+86 15963926799 Yitang Town,Linyi,Shandong,China

Yitang Town,Linyi,Shandong,China