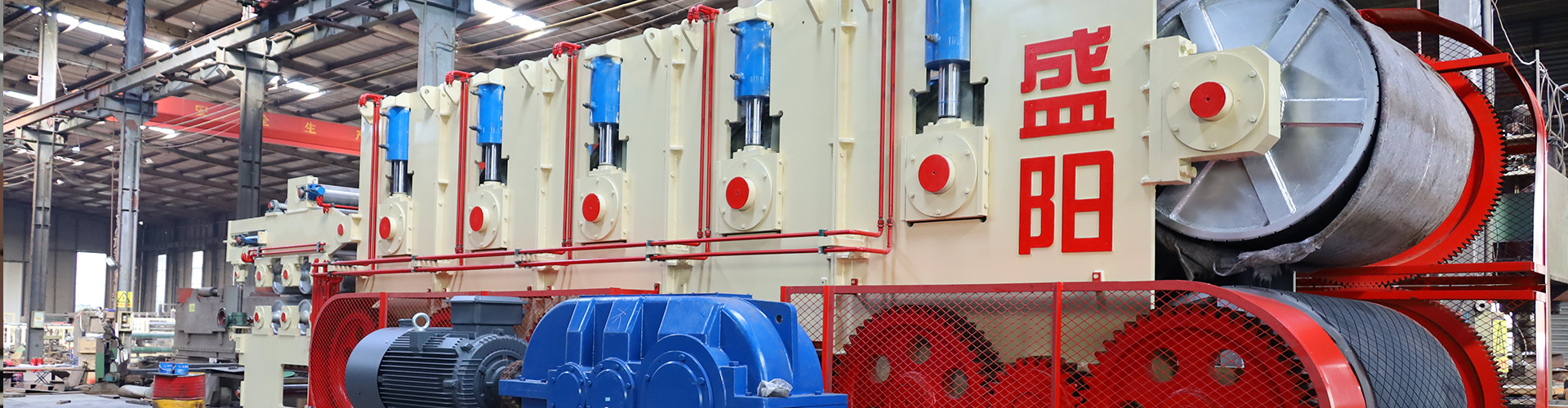

Edge Cutting Saw

|

Place of Origin |

Shandong, China |

|

Condition |

New |

|

Type |

Edge Cutting Saw Machine |

|

Weight (kG) |

1200 kg |

|

Applicable Industries |

Machinery Repair Shops, Other, wood-based panel machinery factory, woodworking machinery, plywood production factory, machinery |

|

Warranty |

1 Year |

|

Key Selling Points |

Easy to Operate |

|

Usage |

Plywood Production |

| Voltage |

380V |

|

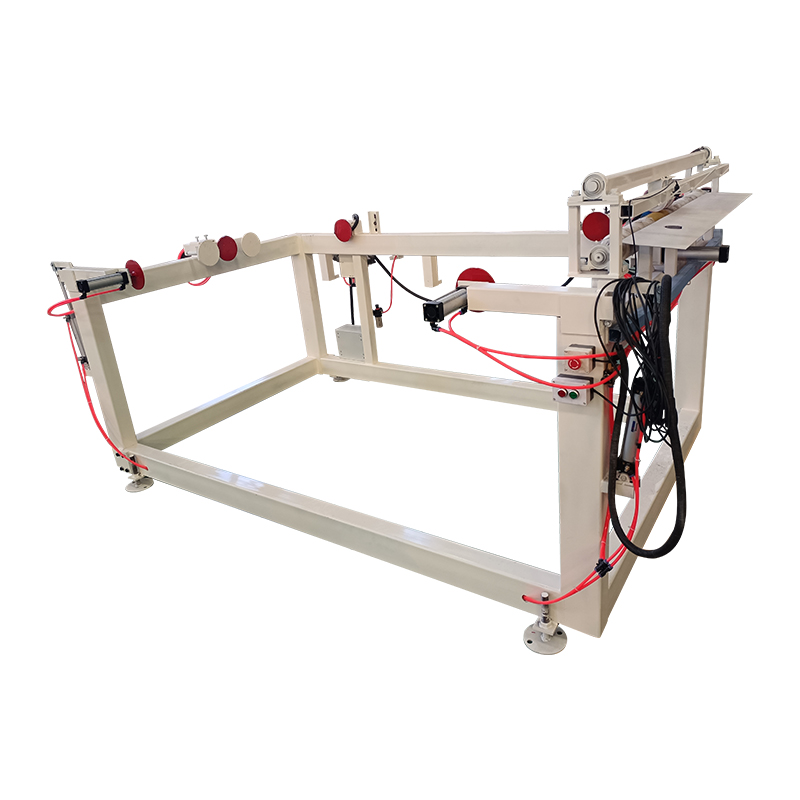

Dimension(L*W*H) |

1220*2440mm |

|

Power (kw) |

44.5kw |

|

Video outgoing-inspection |

Provided |

|

Warranty of core components |

1 Year |

|

Core Components |

Bearing, Motor, Pump, Gear, PLc, Other, Gearbox Pressure vessel, Engine |

|

After-sales Service Provided |

Online Support |

|

Keywords |

Woodworking Panel Saw |

|

Working methods |

CNC Automatic |

|

Certification |

CE ISO9001 |

|

Color |

Customers' Demand |

|

Finished products |

4*8 Feet Plywood |

|

Panel Length |

Beveled Edge 250mm |

|

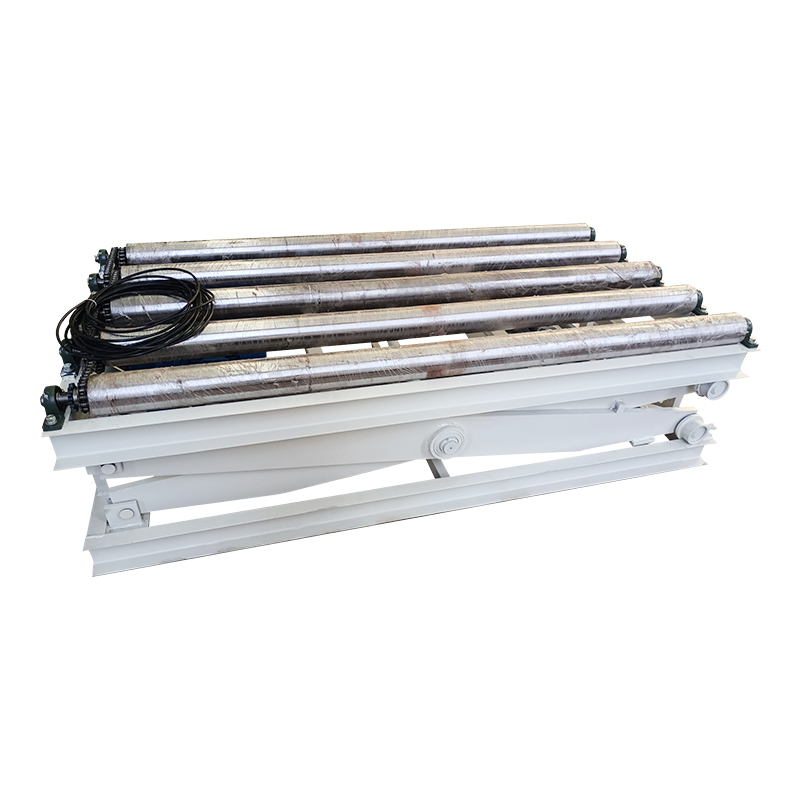

Maximum thickness of saw board |

60mm |

|

Sawing speed |

0-30m/min |

|

Board layout form |

One set of fence type automatic plate arrangement and stacking |

|

Maximum thickness of saw plate |

60mm |

|

Sawboard diagonal error range |

Less than 1mm |

|

Saw plate straightness error range |

Less than 1mm |

|

Sawing speed |

0-30m/min |

|

First saw guide rail |

30mm six-edge guide rail |

|

Second saw guide rail |

φ30 cylindrical guide rail |

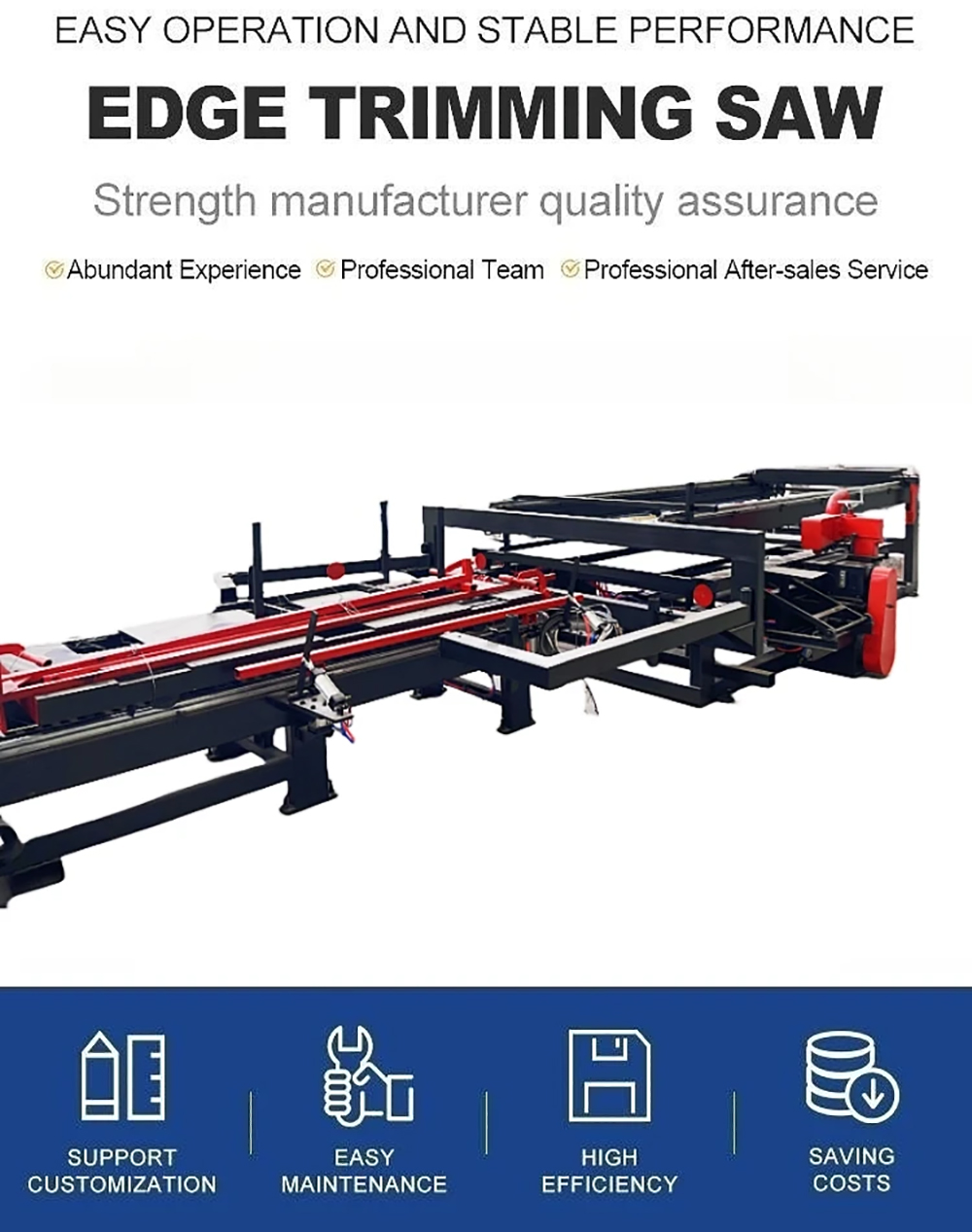

Plywood automatic four-edge trimming saw is widely used in Plywood production line,which is controlled by PLC Control,saw blade speed can be adjusted automatically according to cutting condition,no need to stop any saw blades.

It only need 2 workers,so It could save labor cost and increase production capacity.compared with ordinary hand saws, the machine has five features: precision, high efficiency, energy saving, provincial industry and environmental protection.

Welcome inquiry with details about your product plan.

Advantage

1. The main structure is strong with enoughrigidity and high stability. 2. This saw has high precision anti-wearing guide rail, infrared guidance. 3. High automatic: all working process is controlled by PLC, automatic cutting and stacking. 4. Automatic device to clear and collect the edge strips cut off from the panel. 5. This machine only needs 2 workers for feeding, and automatic feeding style onely need one worker. 6. Servo motor supply the smooth running, high speed,high precise, precise position.

FAQ:

1. Can you customize products for clients?

Yes, We can customize and produce woodworking machines according to the customer’s requirements or drawings.

2. How can we trust your factory?

We recommend that you come to our factory to see the goods, to verify the real situation of the products, and know more about our factory.

3.Why does the price often change?

The price depends on the latest prices of the raw materials.

4. What about the contract signing?

If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit. Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

5. How about delivery?

When the product is ready, it can be delivered to you after your full payment. We’ll provide technical guidance.

You Might Also Like

+86 15963926799

+86 15963926799 Yitang Town,Linyi,Shandong,China

Yitang Town,Linyi,Shandong,China